Friday, December 10, 2010

Assembling a Geiger Counter

After visiting the Smithsonian National Museum of Natural History and seeing the case with minerals that emit radiation, getting a geiger counter seemed like a good tool to have. So after studying various models I bought a Monitor 4 kit from GiegerCounters.com. After receiving the kit and reading the through assembly instructions, I took the time to gather my tools. Having never worked with a Geiger-Müller tube before I was apprehensive toward handling it to the point of considering using latex gloves. After seeing the tube casing, it seemed okay to handle [make sure no contact with the mica window].

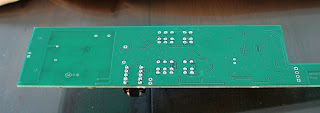

The first step was solder the transformer and two switches on the already prepared circuit board. The manufacturer S.E. International already has the majority of the components surface mounted then wave soldered on the circuit board. It is up to the assembler to solder the through hole parts.

This next image shows the component side of the circuit board with the two switches and transformer installed.

Next the output connector is soldered on and the speaker.

After that the 9 volt battery clip that provides power to the board and the LED guide with red LED are attached.

A diode to mount the meter to is installed along with a a foam piece for circuit board support.

The meter is then soldered to the diode and circuit board foil.

Here is a close up of the Geiger-Müller tube probably made in Tennessee. I did not take pictures of this assemble step because I was concentrating on not breaking this tube.

Once the wires and tube are connected to the circuit, the tests begin. There are several resistance and voltage checks. For the unit I was building, the resistance check did not quite match what my meter showed and the values the manual supplied. I guess it is possible the meters are not calibrated. The voltage checks all looked good. The detector was suppose to detect 5-25 counts per minute (CPM) and I measured 13 CPM and 15 CPM. I then adjusted the three potentiometers to the resistance ranges shown in the manual. A better calibration can be achieved using an oscilloscope and frequency generator. Having neither I am using the detector in its current state of accuracy +/- 20%.

After testing the circuit board, the tube, speaker, and battery clip are placed in the bottom half of the case. The top half then fits over that to complete the case. Five screws lock it all together. I still have to put conformal liquid on part of the circuit board to seal the high-voltage components from moisture. Also once I have my digital meters calibrated I will make some adjustments to the detector.

The labels were attached to the case. Assembly completed.

Fortunately, I found no common items around the house that generate radiation (checked the smoke detectors, granite rock, New Albany shale, potassium chloride salt substitute).

The detector has two sets of switches. Switch 1 has an off, on, on with speaker, and battery test setting. Switch 2 has a 1x, 10x, and 100x setting. So the analog meter can display 0-50000 CPM. The user outputs are a little red LED, an analog meter, and a speaker.

Later, I checked the detector on a Meta-autunite specimen that generated about 300 CPM. It was good to see it working!

Setting the detector to 100x it measured about 8000 CPM on a Torbernite mineral specimen.

All and all, an interesting experience assembling and testing the Monitor 4. I believe the tool will be useful in finding Uraninite specimens.

Learn more about Geiger Counters with Professor Bob Burk (Carleton University - Ottawa, Canada) from this YouTube video:

Labels:

geiger counter,

minerals

Subscribe to:

Post Comments (Atom)

4 comments:

I found it surprising that you got no readings from the granite or KCl. Is this simply a function of the sensitivity of the instrument? What exactly is the instrument reading? Should it read all sorts of radiation, including gamma rays? (I've never used a geiger counter, so I don't know--just curious). In the oil and gas industry, we use gamma ray detectors for logging borehole formations. These show high readings when drilling through shale, granites, or other potassium-rich rocks, so I would have expected a geiger counter to do the same.

Interesting post; I didn't know you could build your own geiger-counter! Are they expensive?

--Howard

Before I answer your questions, let just say I am not an expert in nuclear sciences or analog electronics. Without having a calibrated Geiger counter to compare the one I have to I am not sure if the my KCl or granite samples are emitting much radiation to measure. This web page documents household items that might be radioactive.

The Geiger tube is detecting atomic particles which ionize the gas in the tube. This ionization creates electric current in the tube that can be detected. The Monitor 4 device detects alpha particles (down to 2.5 MeV), beta particles (50 keV-35% efficiency; 150 keV-75% efficiency), gamma & x-rays (down to 10 keV through mica window; 40 keV through sidewall).

Once you have a Geiger-Müller tube you just need to build a high-voltage power supply and pulse detection circuit.

Modern American detectors are somewhat pricey but Russian detectors on eBay can be bought for under $100 (see this blog entry to learn more). One can also find cheaper American detectors from Cold War times on eBay as well.

That is a LNDinc tube made in NY ( http://www.lndinc.com/products/711/ )

Oh and get that thing calibrated at a lab with some NIST sources, I work at one and meters can be so far off that it is astounding that people are using them. Without a good cal you could be reading double or half or 12x time the actual. It's not that expensive just 60ish bucks at the lab I work in, takes a couple of weeks.

If you want to play around with how much your readings can change play around with those three pointometers each one will correspond to a range. Go ahead a twist away your meter is not calibrated anyway and you'll see how much you can and cannot measure.

Thanks for the comment. It is neat the tube is made in New York. I now have an oscilloscope now and can get a frequency generator so I might try to calibrate this device.

Post a Comment